Airplane Song and Rebuild the Engin Again

Back in September 2019, nosotros looked at the process of evaluating a troubled engine to determine only how much work it was going to demand to get it back in the air. The big question for the owner was: Do I overhaul the engine as per the Lycoming Direct Drive Overhaul Manual and replace parts as per Lycoming SB 240W (and similar Superior publications), or practice I repair and supercede parts equally necessary (Islamic republic of iran) and forego the power to call it an overhaul?

Overhaul vs. Islamic republic of iran Decision

At first, the decision to go ahead and perform a major overhaul seems uncomplicated enough. Wouldn't it exist worthwhile to be able to say the aeroplane has an engine with null hours since major overhaul (SMOH)? While it is plainly worth something, the question is: Does it add enough value to offset the cost?

That answer is non so obvious. Equally you may call up, the engine in question has 281 hours total time since new (TTSN). The deviation in value of an airplane with a 300-hour engine versus a newly overhauled engine is not very much. But the toll difference turns out to be several thousand dollars. The principal benefit of the overhaul is that when you become to sell the airplane you tin can simply say the engine had a lot of rust in it so we overhauled it. On the other mitt, the Islamic republic of iran conclusion ways y'all will accept to explain why you didn't follow the overhaul guidelines and just replaced certain parts.

And then why is there such a large added cost for the overhaul? Go on in heed that a 300-hour engine is non exactly worn out. That includes all of the accessories such as magnetos, fuel pump, alternator, ignition wires, and fuel-injection arrangement. If in that location is no corrosion harm, these parts are in almost-new condition. Simply overhauling the magnetos alone would contribute $1400 to the engine overhaul cost. With the IRAN conclusion comes the ability to get another 200+ hours out of these parts. Most people would not overhaul cylinders when doing an engine overhaul; they would supervene upon them, though this is not a requirement. All of these things add upwards.

As it turns out, the listing of replacement parts in a corroded engine is based nearly entirely on the extent of the corrosion. This leaves a few items to possibly keep equally is—but in the case of this engine it turned out to be very few. In fact, many items had to be replaced that would not unremarkably require replacement in a more typically worn out engine.

In the end, the owner decided to do a complete overhaul using bored out and reconditioned cylinders. This seems like a good compromise nether the circumstances. When this owner bought the aircraft, a sale toll was negotiated based on the assumption that a lot of work would be required to make the engine airworthy again. No one was under any illusion that the airplane would be flyable any fourth dimension soon.

The Ravages of Corrosion

For those of you who missed the first article, we should probably review how we got here. When the owner purchased this RV-6A, he knew it had been sitting for a long time with very niggling flight fourth dimension over several years. Corrosion was high on the list of potential problems as he began the pre-purchase inspection. A borescope exam showed a lot of rust in the cylinders.

Later the purchase, equally the physical inspection proceeded, the goal was to not exist whatsoever more than invasive than necessary until the scope of the corrosion damage was clear. This began with the process of carefully removing each cylinder, installing a torque plate, and checking the cam and lifters visible at each removed cylinder location. The extra care was exerted in the hope that the engine cases would not demand to exist carve up apart. This proved to exist wishful thinking, merely a prudent course until more information was known fabricated sense. It didn't take long to meet that the cam and lifters were seriously damaged by corrosion. From in that location it was off to the engine shop for a complete teardown.

The Process

The valve covers, rocker arms and pushrods were removed. The pushrods were heavily corroded, so out they went. This is a rare cost to deport on a normal overhaul. Every bit the case came apart, at that place was corrosion on the drive gear to the fuel pump, besides. These accessory drive gears are rarely replaced, but this one showed articulate signs of pitting. These little gears are expensive, or at to the lowest degree they seem so for such a small-scale office. The crank and rods looked good, so they were set bated for Magnaflux inspection.

A large surprise was the amount of corrosion on the impulse couplers on both magnetos. Yes, this Superior engine had two magnetos with impulse couplers instead of the more than typical i with and ane without. Both mags went over to Aero Accessories for 500-hr IRAN inspection and cleanup. So much for saving coin by non overhauling all of the accessories.

The alternator got the kick when the owner discovered that information technology was an internally regulated Nippondenso unit of measurement. A new B&C alternator with an external regulator and over-voltage protection took its place. This was an upgrade rather than an overhaul determination. The old fuel pump also got replaced with an overhauled unit. In the finish, the only accompaniment to escape replacement or overhaul was the starter.

With all the damage that this engine had, you would call back information technology had been sitting one-half in and half out of the sea for a few weeks, but that was not the case. This was the result of several years of almost no flying and no effort to preserve the engine when information technology was sitting. This is what can happen to a airplane that doesn't fly. If yous buy an plane like this one that has had picayune or no flying in several years, don't be surprised if y'all observe the same matter. Of course, a dry desert climate will exist more forgiving of such neglect, and a moist climate, peculiarly one virtually salt h2o, will exist even harder on an engine.

The Overhaul Process

For those who take not been through this drill before, it might seem that the overhaul procedure should be pretty straightforward, with an easily determined price. Unfortunately, this is not the case. Many questions come upwards that have a big impact on the cost. Can major parts such as the crankshaft, camshaft, and engine cases be used as is, do they need to be repaired, or do they need to be replaced? Each of these items costs thousands of dollars.

Many Lycoming crankshafts must exist replaced at the time of overhaul equally per a Lycoming service bulletin. This was a Superior engine, so that was not a business organisation, but for many owners it could be. While the owner of an Experimental/Amateur-Built shipping could choose to ignore this requirement (or not, depending on the language in the plane'south operating limitations), it would exist hard to detect a reputable shop that would overlook this requirement. The same applies to other components that may be subject field to Airworthiness Directives or Service Bulletins.

Many shops will quote a preliminary estimate for an overhaul, based on reusing the cam and lifters, just the truth is many engines need to take these items replaced at a cost of around $2000 for a four-cylinder engine. Cases typically need rework at overhaul time, but sometimes they take cracks that need welding or may be so severe that the instance needs to be replaced. The inspection is covered in the overhaul approximate, but repair or replacement seldom is unless it is known in advance. The last replacement particular is cylinders.

Most shops exercise non want to rebuild cylinders that take 2000 hours on them, the typical overhaul time. This is because the aluminum cylinder heads fatigue over time and will eventually crack. Replacement cylinders should be covered in the overhaul price unless the existing cylinders have less time on them than the rest of the engine. This is a judgment call. New cylinders run $1200 to $1500 each, with an overhaul of a cylinder running almost half that.

With our RV-6A engine, the cylinders had less than 300 hours on them, so overhauling them made a lot of sense. Even so, they did need to be bored out to 0.010-inches oversize to clean up the rust. This, in plough, required new oversized pistons and rings. The crankshaft checked out fine and could be reused with no machine work, as did the cases. This saved some coin but would not exist a normal matter in about overhauls.

Bottom Line

The beak for all of this work came to about $16,000, which is non a bad bargain because what had to be done. The owner also chose to overhaul the fuel-injection servo because of how long it had been sitting. The engine mounts were also sagging, so that added another $700 to the cost including new bolts.

The worst office of the overhaul, side by side to the toll, is the fourth dimension it takes to consummate it. Pocket-size shops where the owner does all of the last assembly can only plow out the work so fast, specially when in that location are a dozen engines in line ahead of you. Some of this is because of exterior piece of work, such as inspections and possible rework of components, and some of information technology is just waiting for parts. But some of it is just waiting in line for your plow. Don't be surprised if it takes two or three months to become your engine dorsum from a decorated shop.

Installing the Overhauled Engine

While waiting for the engine shop to exercise its piece of work, at that place was fourth dimension to tidy up the firewall. Some penetrations needed to exist modified to make them safer, others simply needed a new coat of 2000° sealant that was showing signs of age. The owner wisely took advantage of the improved work space (produced by the engine being out) to take care of these items and just clean everything up.

While he had time on his hands, he decided to add an Anti Splat nose-gear stiffener (aka Olfactory organ Job) and Lip Slip. These are designed to help prevent nose-gear collapse in the case of a nosewheel landing or crude-field piece of work. These products have gained some popularity amid RV owners. New brake lines, a parking restriction, and sealed bike bearings as well got installed during the down time. That'due south what happens when engineers sit around with aught else to do.

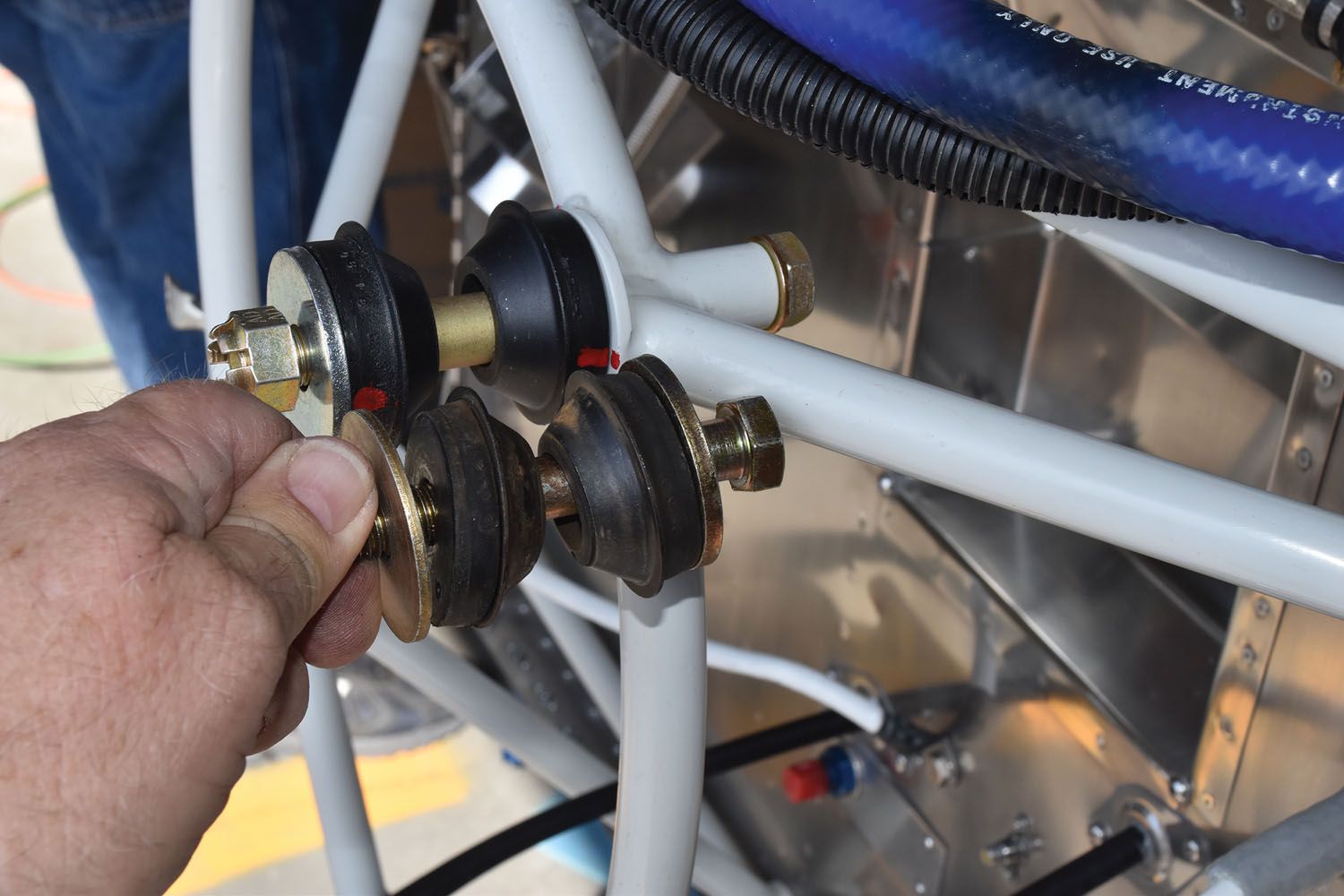

With all of the preparation out of the way, information technology was time to hang the newly refurbished engine back on the airplane. This required removing the left magneto due to clearance issues, just was otherwise straightforward. I difference seen with this plane was the use of conical engine mounts. We rarely run across conical mounts except on former engines, but the original builder ordered the engine that way from Superior. The advantage of the conical mount system is that it limits engine movement, something that tin can be important in a closely cowled engine. This is non usually seen as an important result with the RV-6A, but that was the architect's preference. The downside to conical mounts is their trend to transmit more vibration to the airframe.

The conical mountain vibration upshot was at to the lowest degree partly addressed by using some sophisticated (expensive) engine-mountain bushings. These mounts crave a specific orientation that is maintained past some roll pins installed into the engine mount and lock into the back side of the bushings.

The rest of the installation went smoothly with no surprises, except for the intake air box that needed a lilliputian tuning up. As this is written, the owner is making some adjustments to the cowl to better align the intake with the air box, merely otherwise it is set to fly.

The engine will be filled with non-detergent (mineral) oil for the break-in catamenia. This should remain until oil consumption has stabilized, normally after 10 to 25 hours. During this time, the engine should be run at fairly high power settings (65-75% power), and engine temperatures should be monitored closely. Although a return to Phase I is not required for an engine overhaul, it is prudent to gear up bated a flight-examination catamenia of at least a few hours to be sure everything is working properly and that there are no leaks.

Conclusion

We can take a few lessons from this story. Ane, every bit the song says, rust never sleeps. Corrosion is always a business with steel parts that are non protected. The best way to stave off corrosion in an plane engine is to fly information technology regularly or preserve it properly when it will be left unflown for xxx days or more than. More rigorous measures are manifestly called for in damper climates.

When purchasing a used aeroplane that has not flown much, you should not get seduced by a low total time number. Lycoming lists a TBO for most of its engines equally 2000 hours or 12 years, because time is every bit equally much the enemy of long engine life as hours of employ—in many cases more and so. Finally, the cost of an engine overhaul is not only measured just in dollars merely also in time.

This owner got a discount of almost $20,000 off the normal price when he bought this aeroplane, merely past the time the overhaul cost was added to months of insurance and hangar hire, non to mention his personal fourth dimension, the disbelieve he got was just about a break-even proposition. He is still happy with the deal he made, simply he had to work for that discount.

Source: https://www.kitplanes.com/engine-overhaul-part-ii-iran-vs-overhaul/

0 Response to "Airplane Song and Rebuild the Engin Again"

Enviar um comentário